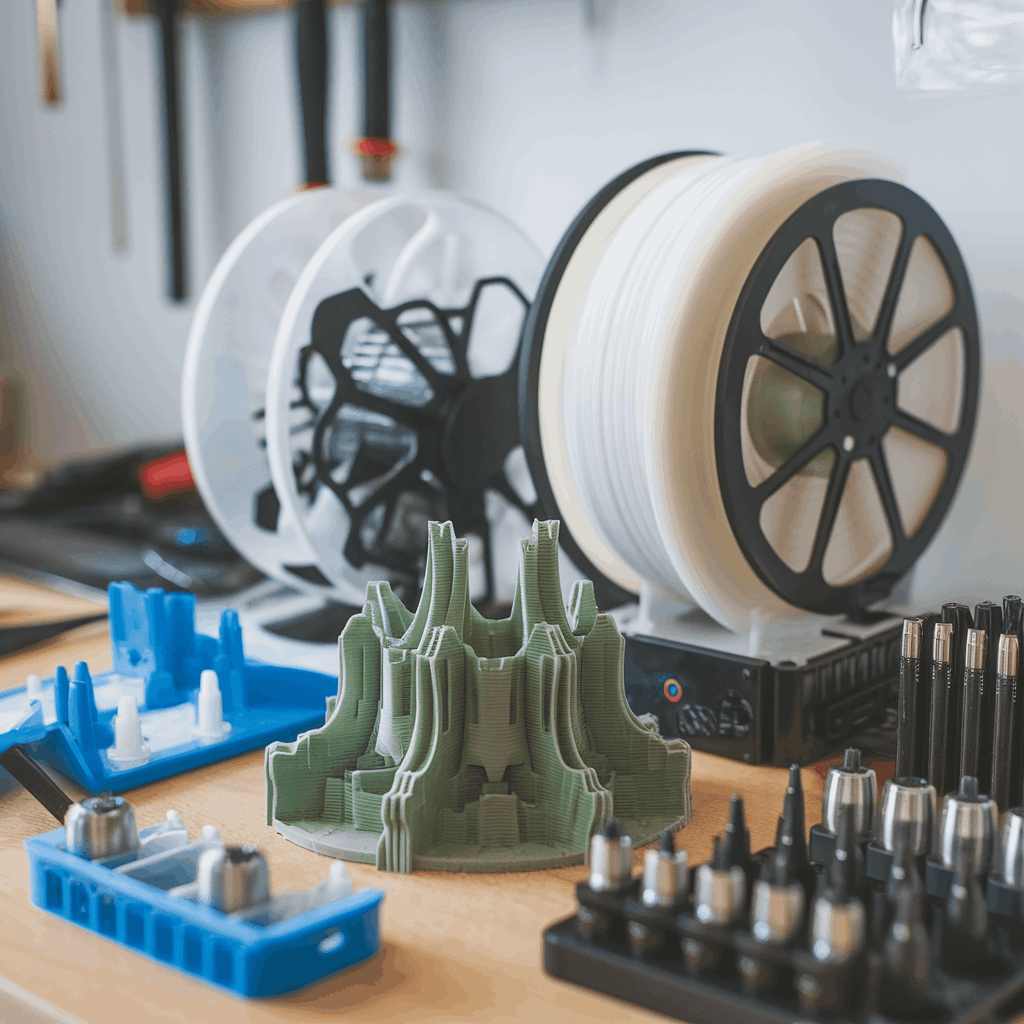

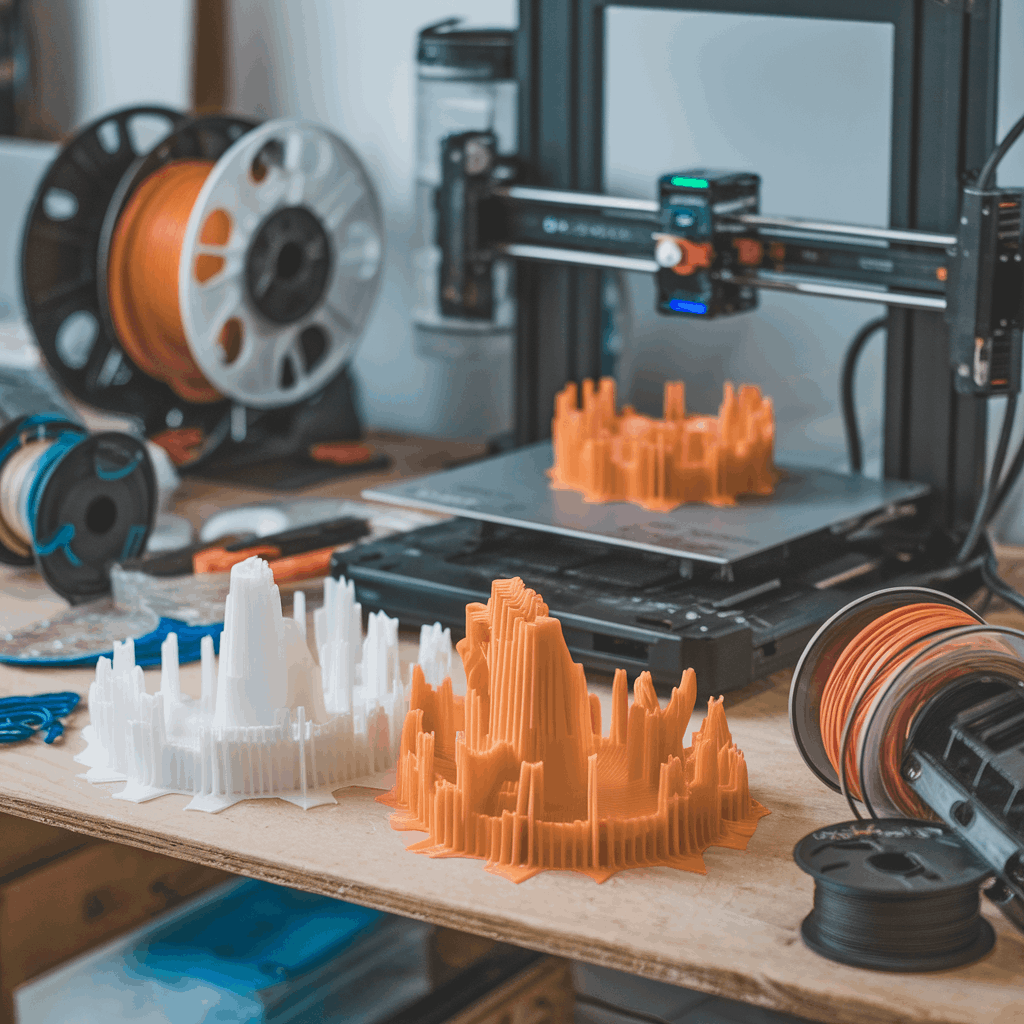

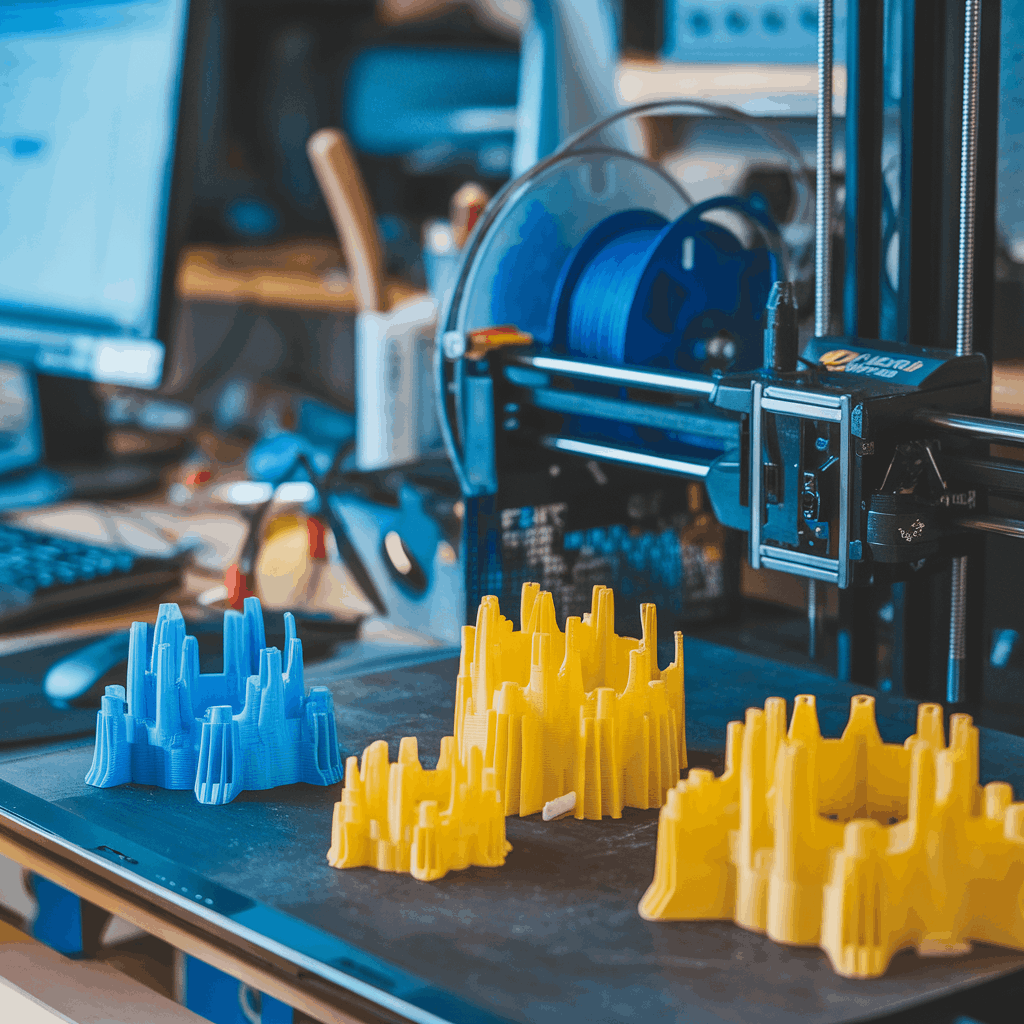

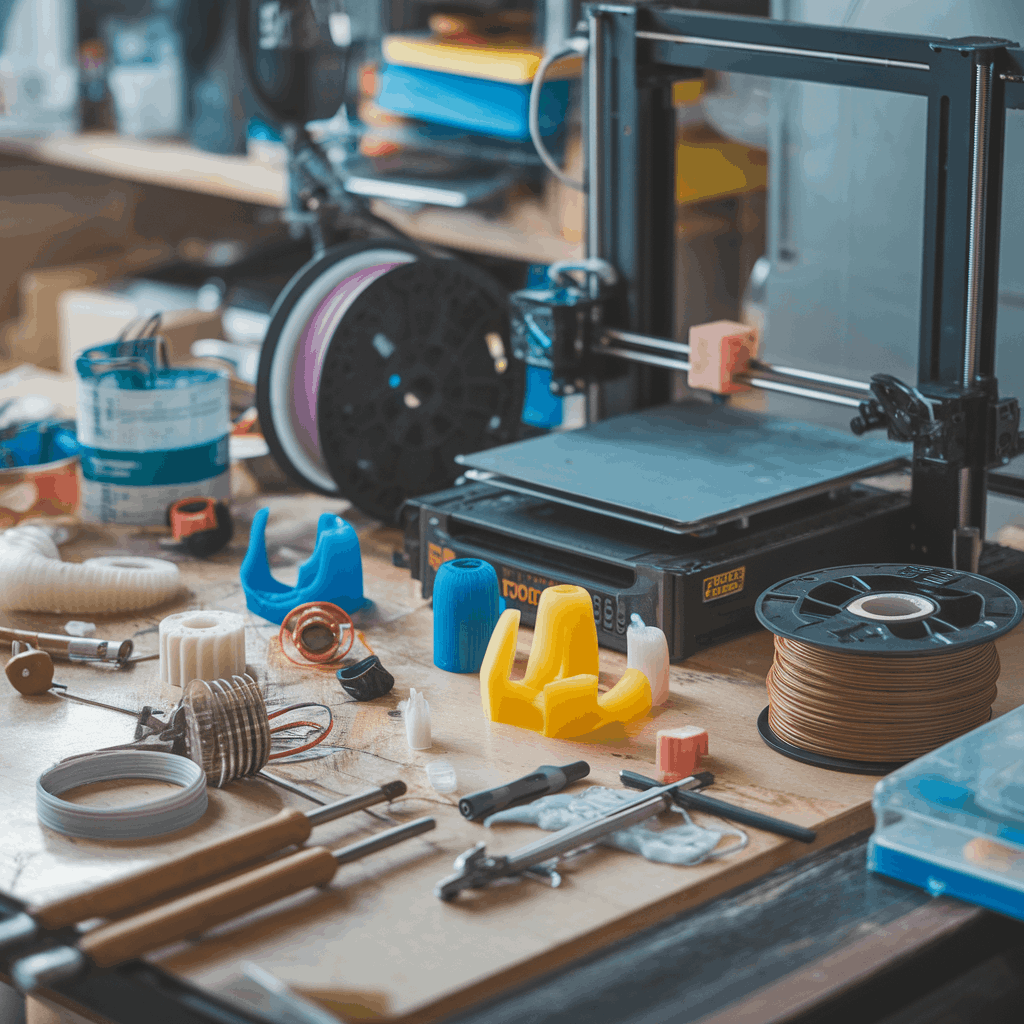

Custom Support Structures

We design and fabricate breakaway and soluble supports optimized for your models. Lattice density and interface thickness are tuned for clean removal.

- PVA, HIPS, BVOH, breakaway blends

- Support kits by printer model

- Digital files included on request